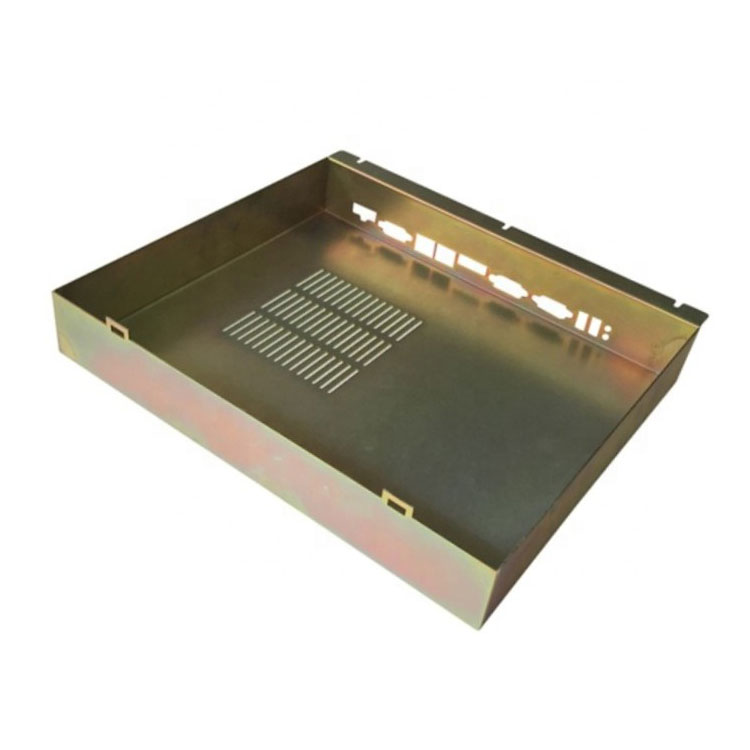

Precision customized sheet metal stamping parts

Detail Information

| Keywords: | Equipment accessories, electrical box shell, case shell, bending shell, stamping shell, sheet metal shell | Materials: | Sus, Aluminum,Iron,Brass,Alloy, etc. |

| Thickness: | 0.2-0.5mm, According To Customer Request. | Tolerance: | Laser Cutting And Bending: ±0.1mm, Stamping: ±0.02mm,Welding: ± 0.5mm |

| Shape: | According To Customer’s Drawing Or Request | Size: | Customized Size |

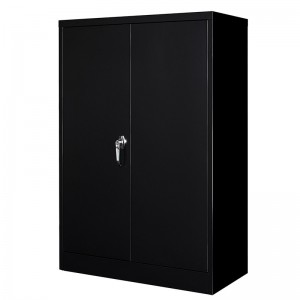

| Application: | Furniture, office, computer, refrigerator, oven, storage cabinets, cabinets, etc | Drawing Accepted: | All Formats(UG,ProE, Auto Cad, Solidworks, And So On) |

| Machining: | Laser Cutting, Bending,welding, Polishing,chrome, Etc. | Finish: | Chrome, Powder Coating, Black And Other Color Drawing |

| Type: | Large equipment housing | Service Mode: | OEM customized |

| Standard: | Custom High Precision Non-Standard | Surface treatment: | Powder coating,chrome,polish,hot dip zinc |

Product Description

Custom SUS plate welding iron alloy sheet metal box manufacturers

The general technical parameters are as follows, which can be customized according to different requirements:

Materials: high quality cold rolled steel sheet, galvanized sheet, stainless steel, etc. Thickness 0.8-2mm

Technical parameters

1: The box body is made of 1.0mm thick high-quality cold-rolled steel plate with baking paint. (201 stainless steel and 304 stainless steel can also be used)

2: Convection ventilation of air in the box; It can effectively protect the aging of electrical equipment in the box and damage caused by excessive temperature;

3: Outdoor polyurethane plastic powder is used on the surface of the box; After baking at high temperature, it can ensure that it will not age, crack and turn yellow in the outdoor exposure environment.

4: The sealing ring of the box door is made of polyurethane foam on site; The overall appearance is beautiful; Avoid falling off and water seepage, and the protection grade shall reach IP55.

Form Parameter

| Item | custom SUS plate welding iron alloy sheet metal box manufacturers |

| Material | Stainless steel, iron, aluminum, alloy, brass, and so on. |

| Thickness | 0.2-50mm depends |

| Tolerance | laser cutting and bending: ±0.1mm, press stamping: ±0.02mm. pipe bending: ±0.2mm |

| Size or shape | According to customer drawing or request |

| Application | Used Widely. Schools, hotels, guesthouses, factories, etc |

| Drawing accepted | All formats(CAD, PDF, SOLIDWORKS,ProE,UG,etc.) |

| Machining | Laser cutting, punching, bending, reviting, welding, polishing, brushing, etc. |

| Quality Control | ISO 9001, 100% QC Test before shipment. |

| Cost control | Advanced equipment, reduce labor costs; Strict quality control, reduce defective rate, ensure delivery time. |

| after-sale guarantee | If the quality problem is caused by our fault, we will take 100% responsibility. |

| Surface treatment | Polishing, brushing, chrome,electroplating, powder coating,hot dip,spraying, anodizing, etc. |

| Delivery Time | 7-30 days |

| Company Type: | Factory & manufacturer |

| Service mode | OEM or ODM, customized |

| Certificate | ISO 9001 |

| Feature or advantage | R&D ability, FREE design, All in one solution.cost reduction. |

| Experience | OEM & ODM since 2012 |

| Keywords: | Custom SUS Plate Welding Iron Alloy Sheet Metal Box Manufacturers | Materials: | Sus Plate, Aluminum,and So On |

|---|---|---|---|

| Thickness: | 0.2-50mm, Or Custom Request. | Tolerance: | Laser Cutting And Bending: ±0.1mm, Press Stamping: ±0.02mm, Tube Bending:±0.2 |

| Shape: | According To Customer’s Drawing Or Request | Size: | Customized Size |

| Application: | Industry, Agriculture, Indoor, Outdoor, Machinery, Chemical, Pharmaceutical And So On | Drawing Accepted: | All Formats(UG,ProE, Auto Cad, Solidworks, And So On) |

| Machining: | Laser Cutting, Bending,welding, Polishing,chrome, Etc. | Finish: | Chrome, Powder Coating, Black And Other Color Drawing |

| Type: | Hardware Parts,OEM Parts | Service Mode: | Custom Processing, Oem, Odm. |

| High Light: |

IP55 iron sheet box, Alloy Iron Sheet Box , 0.2mm sheet metal boxes |

||