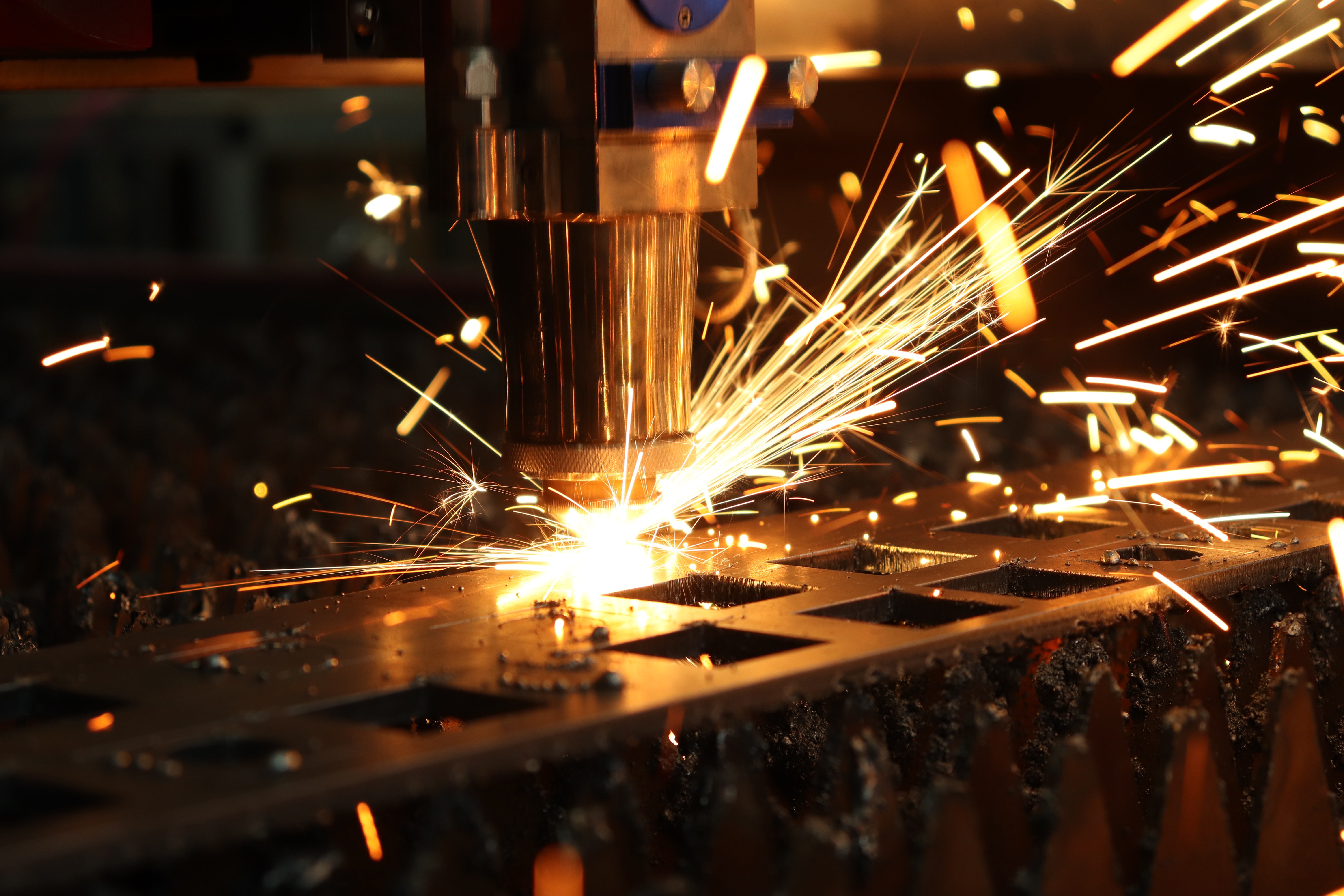

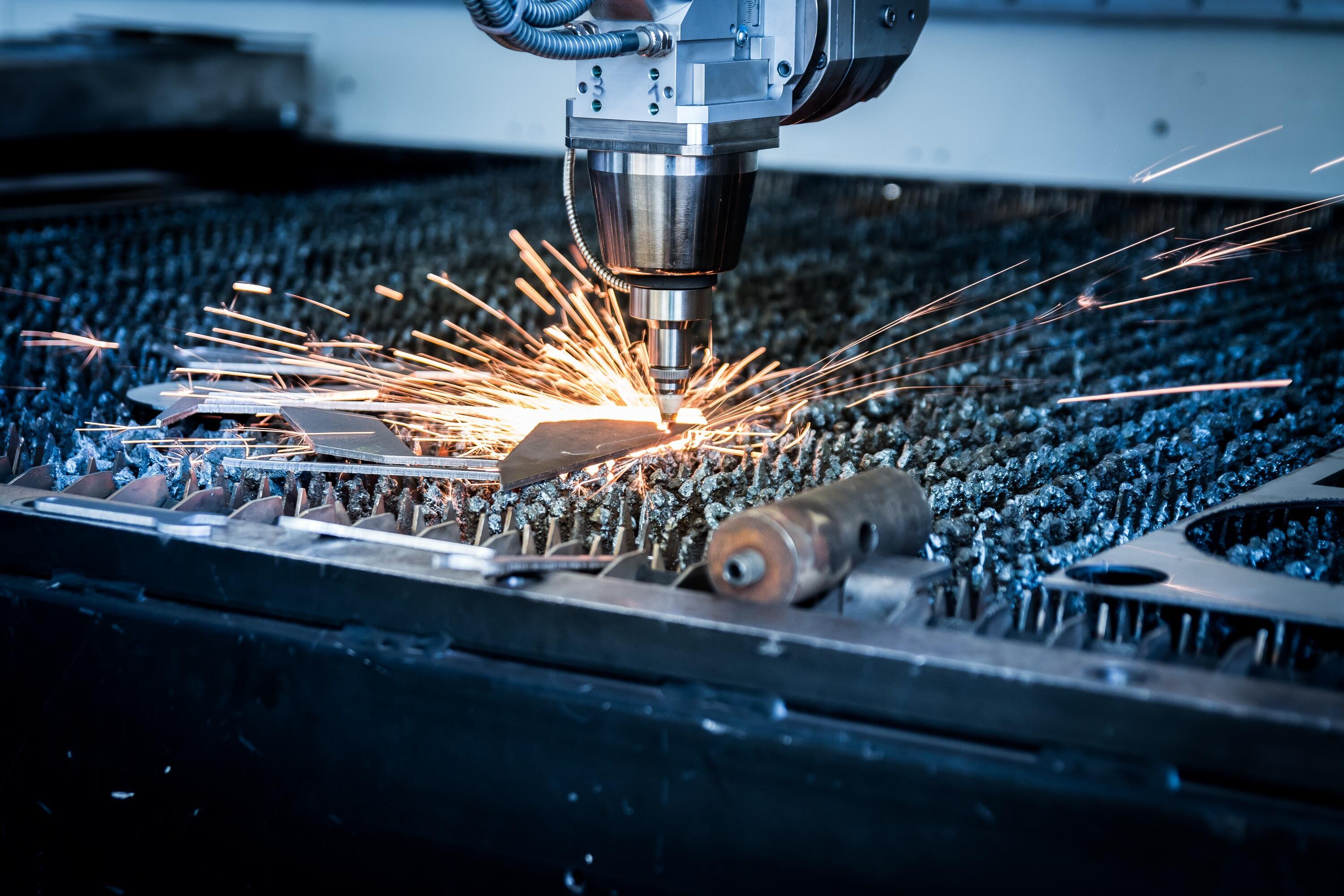

In custom sheet metal processing, laser cutting has become one of the core processes due to its ultra-high precision. It uses a laser beam with high energy density to irradiate the material, causing the material to melt, vaporize or ionize rapidly, thereby achieving precise cutting. Compared with traditional cutting methods, laser cutting does not require molds, can flexibly handle complex patterns, and the cut edges are smooth without burrs, reducing subsequent grinding procedures. Whether it is stainless steel, carbon steel or aluminum alloy, laser cutting can process them efficiently. It is especially suitable for small-batch and multi-variety customization needs, providing strong support for the rapid R&D and production of sheet metal products.

Our advantages

Our company is equipped with multiple high-precision laser cutting machines, which can meet the sheet metal cutting needs of different thicknesses and materials, helping customers shorten the production cycle.