Precision customized sheet metal stamping parts – LAMBERT

Precision customized sheet metal stamping parts – LAMBERT Detail:

Detail Information

| Keywords: | Equipment accessories, electrical box shell, case shell, bending shell, stamping shell, sheet metal shell | Materials: | Sus, Aluminum,Iron,Brass,Alloy, etc. |

| Thickness: | 0.2-0.5mm, According To Customer Request. | Tolerance: | Laser Cutting And Bending: ±0.1mm, Stamping: ±0.02mm,Welding: ± 0.5mm |

| Shape: | According To Customer’s Drawing Or Request | Size: | Customized Size |

| Application: | Furniture, office, computer, refrigerator, oven, storage cabinets, cabinets, etc | Drawing Accepted: | All Formats(UG,ProE, Auto Cad, Solidworks, And So On) |

| Machining: | Laser Cutting, Bending,welding, Polishing,chrome, Etc. | Finish: | Chrome, Powder Coating, Black And Other Color Drawing |

| Type: | Large equipment housing | Service Mode: | OEM customized |

| Standard: | Custom High Precision Non-Standard | Surface treatment: | Powder coating,chrome,polish,hot dip zinc |

Product Description

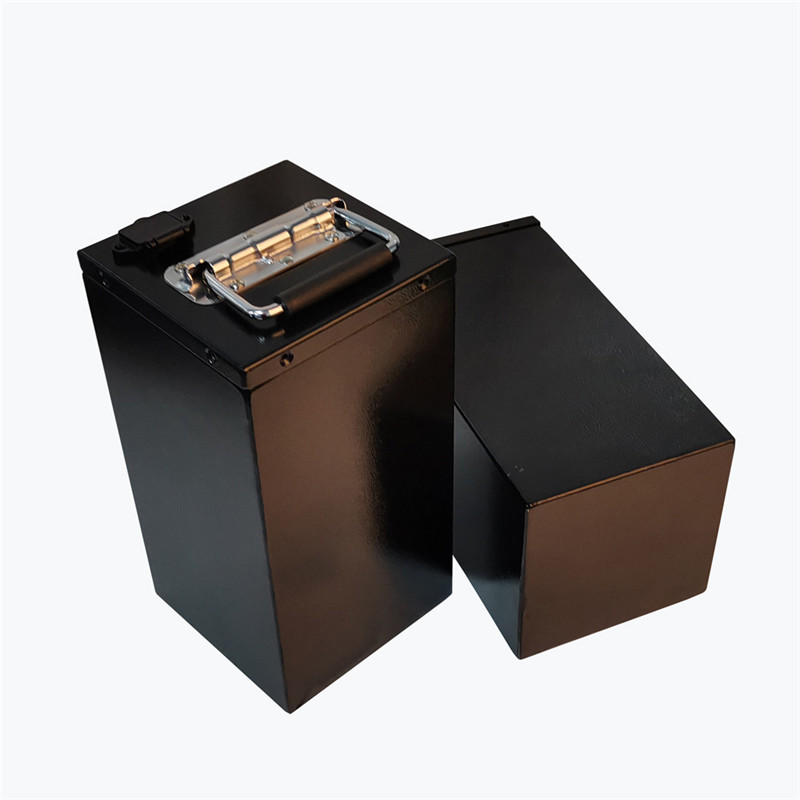

Custom SUS plate welding iron alloy sheet metal box manufacturers

The general technical parameters are as follows, which can be customized according to different requirements:

Materials: high quality cold rolled steel sheet, galvanized sheet, stainless steel, etc. Thickness 0.8-2mm

Technical parameters

1: The box body is made of 1.0mm thick high-quality cold-rolled steel plate with baking paint. (201 stainless steel and 304 stainless steel can also be used)

2: Convection ventilation of air in the box; It can effectively protect the aging of electrical equipment in the box and damage caused by excessive temperature;

3: Outdoor polyurethane plastic powder is used on the surface of the box; After baking at high temperature, it can ensure that it will not age, crack and turn yellow in the outdoor exposure environment.

4: The sealing ring of the box door is made of polyurethane foam on site; The overall appearance is beautiful; Avoid falling off and water seepage, and the protection grade shall reach IP55.

Form Parameter

| Item | custom SUS plate welding iron alloy sheet metal box manufacturers |

| Material | Stainless steel, iron, aluminum, alloy, brass, and so on. |

| Thickness | 0.2-50mm depends |

| Tolerance | laser cutting and bending: ±0.1mm, press stamping: ±0.02mm. pipe bending: ±0.2mm |

| Size or shape | According to customer drawing or request |

| Application | Used Widely. Schools, hotels, guesthouses, factories, etc |

| Drawing accepted | All formats(CAD, PDF, SOLIDWORKS,ProE,UG,etc.) |

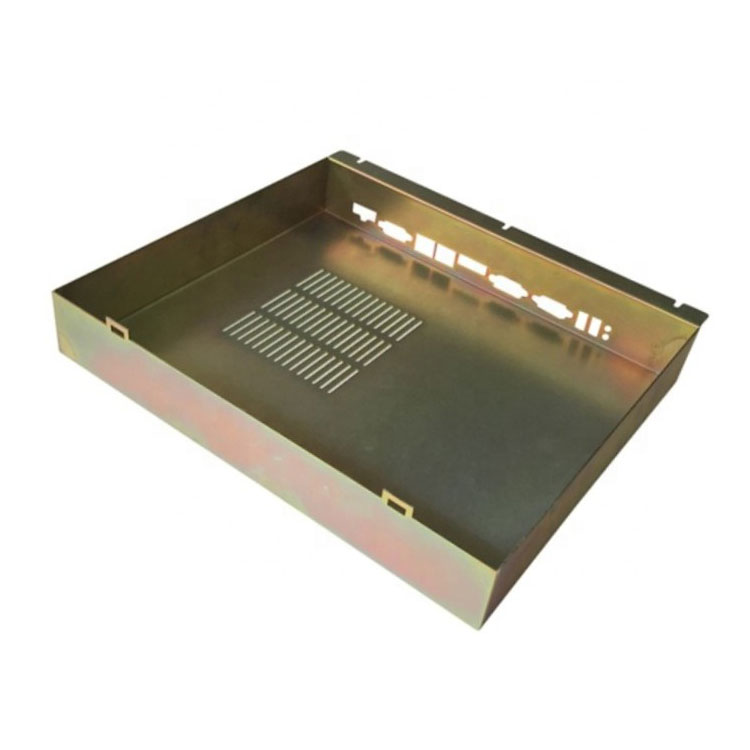

| Machining | Laser cutting, punching, bending, reviting, welding, polishing, brushing, etc. |

| Quality Control | ISO 9001, 100% QC Test before shipment. |

| Cost control | Advanced equipment, reduce labor costs; Strict quality control, reduce defective rate, ensure delivery time. |

| after-sale guarantee | If the quality problem is caused by our fault, we will take 100% responsibility. |

| Surface treatment | Polishing, brushing, chrome,electroplating, powder coating,hot dip,spraying, anodizing, etc. |

| Delivery Time | 7-30 days |

| Company Type: | Factory & manufacturer |

| Service mode | OEM or ODM, customized |

| Certificate | ISO 9001 |

| Feature or advantage | R&D ability, FREE design, All in one solution.cost reduction. |

| Experience | OEM & ODM since 2012 |

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for Precision customized sheet metal stamping parts – LAMBERT , The product will supply to all over the world, such as: Jordan, Swedish, Paraguay, In the new century, we promote our enterprise spirit "United, diligent, high efficiency, innovation", and stick to our policy"basing on quality, be enterprising, striking for first class brand". We would take this golden opportunity to create bright future.

Lambert sheet metal custom processing solutions provider.

With ten years of experience in foreign trade, we specialise in high precision sheet metal processing parts, laser cutting, sheet metal bending, metal brackets, sheet metal chassis shells, chassis power supply housings, etc. We are proficient in various surface treatments, brushing, polishing, sandblasting, spraying, plating, which can be applied to commercial designs, ports, bridges, infrastructure, buildings, hotels, various piping systems, etc. We have advanced processing equipment and a professional technical team of over 60 people to provide high quality and efficient processing services to our customers. We are able to produce sheet metal components of various shapes to meet our customers’ complete machining needs. We are constantly innovating and optimising our processes to ensure quality and delivery, and we are always “customer focused” to provide our customers with quality service and help them achieve success. We look forward to building long-term relationships with our customers in all areas!

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.