No. 18 Shangji Road, Rainbow Avenue, West District, Zhongshan City, Guangdong Province,China [email protected]

No. 18 Shangji Road, Rainbow Avenue, West District, Zhongshan City, Guangdong Province,China [email protected]

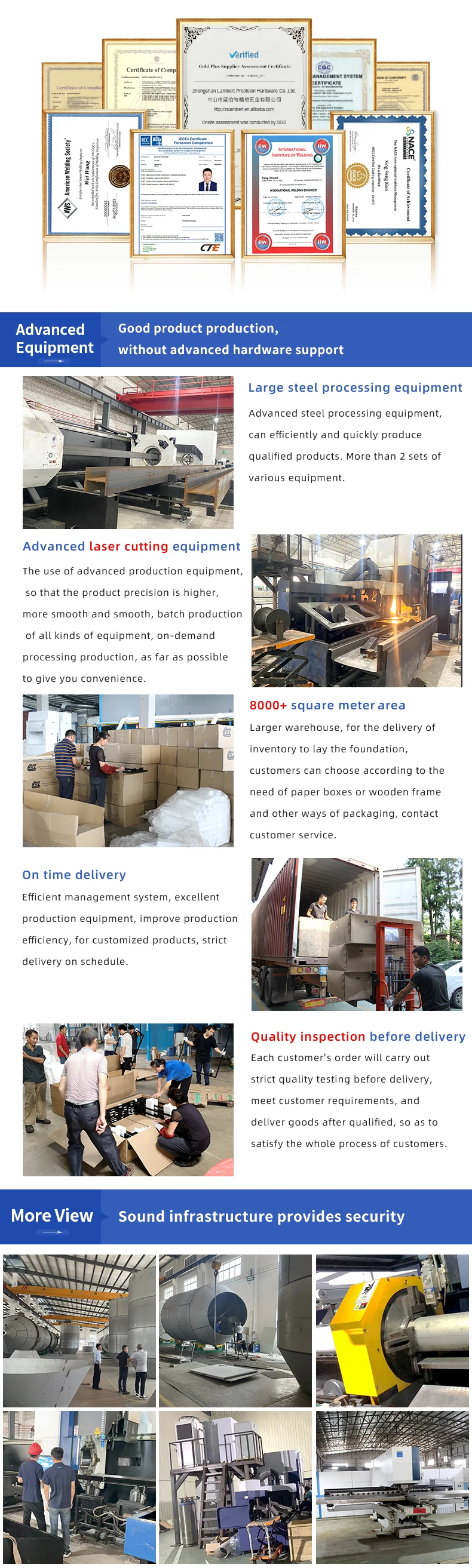

Quotation:According to your drawing(size, material, thickness,processing content, and required technology, etc)

Material:Carbon steel, stainless steel,SPCC,SGCC, pipe, galvanizedsheet,aluminum, copper, etc.

Processing:Laser cutting, bending, riveting, drilling, welding,sheet metal forming,assembly, etc.

Surface Treatment:Brushing,Polishing,Anodizing,Powder Coating, Plating,Silkscreen printing, Sandblast, etc

Tolerance:+/-0.2mm,100% QC qualityinspection before delivery,can provide qualityinspection form

Logo:Silk print, Laser marking

Main Products

|

High-end custom |

Sheet metal bending |

Sheet metal welding |

Metal frames |

laser cutting |

Polished, plated |

|

Custom Metal Chassis |

custom table stand |

Metal enclosure |

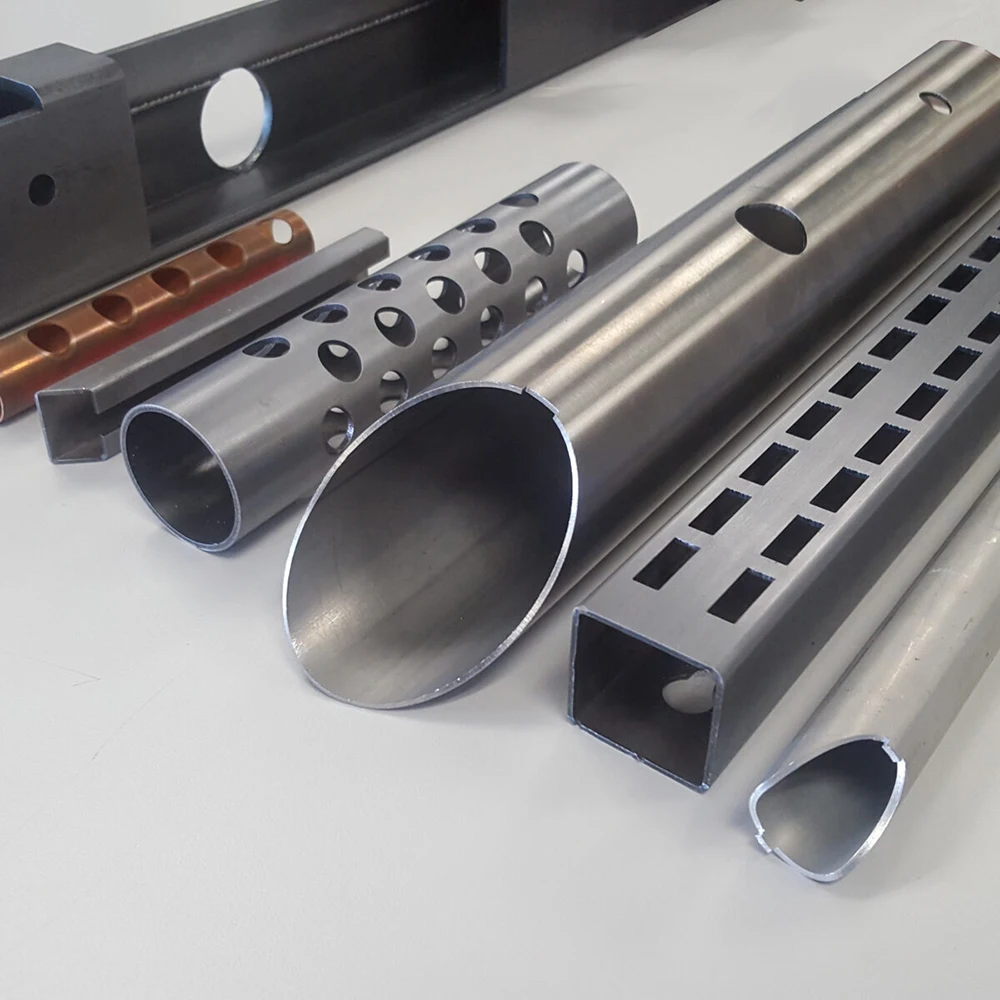

Professional Stainless Steel Aluminum Laser Cutting Machining Custom Tool Sheet Metal Perforated Bending Fabrication Service

Precision OEM Custom Made Services Sheetmetal Bending Stamping 304 Stainless Steel Parts Sheet Metal Fabrication

OEM ODM Custom Laser Metal Cutting & Tube Laser Cutting Services for Sheet Metal Enclosure & Custom Fabrication Sheet Metal

Steel Manufacturing OEM Custom Metal Tube Fabrication Sheet Metal Parts Laser Cut Metal Fabrication Welding Services