Card 1, No. 41-4, Dayou South Street, Xiaolan Town, Zhongshan City, China [email protected]

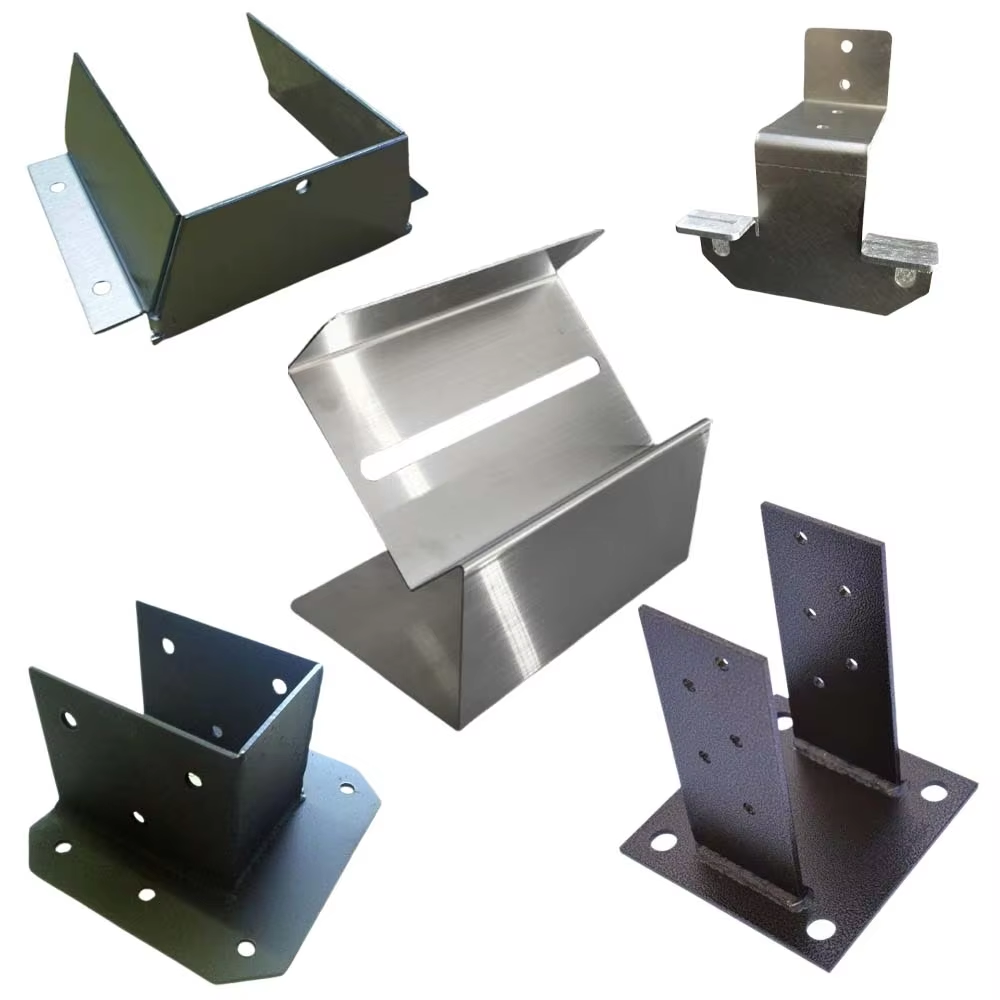

Zhongshan Lambert Precision Hardware Co., Ltd. offers comprehensive welding fabrication services tailored to meet the diverse needs of global industries. With 12 years of export expertise and an ISO certification, we have established ourselves as leaders in high-end sheet metal and tubular fabrication, including welding services. Our 6,000m² Industry 4.0 production base is equipped with advanced MIG/TIG welding machinery, ensuring that every welding project we undertake meets the highest standards of precision and durability. Whether it's for industrial enclosures, architectural metalwork, or public infrastructure components, our welding fabrication services guarantee solutions that are both structurally robust and aesthetically pleasing. We pride ourselves on our attention to detail, commitment to quality, and innovative approach to welding fabrication services, making us the preferred choice for clients seeking exceptional results.