Card 1, No. 41-4, Dayou South Street, Xiaolan Town, Zhongshan City, China [email protected]

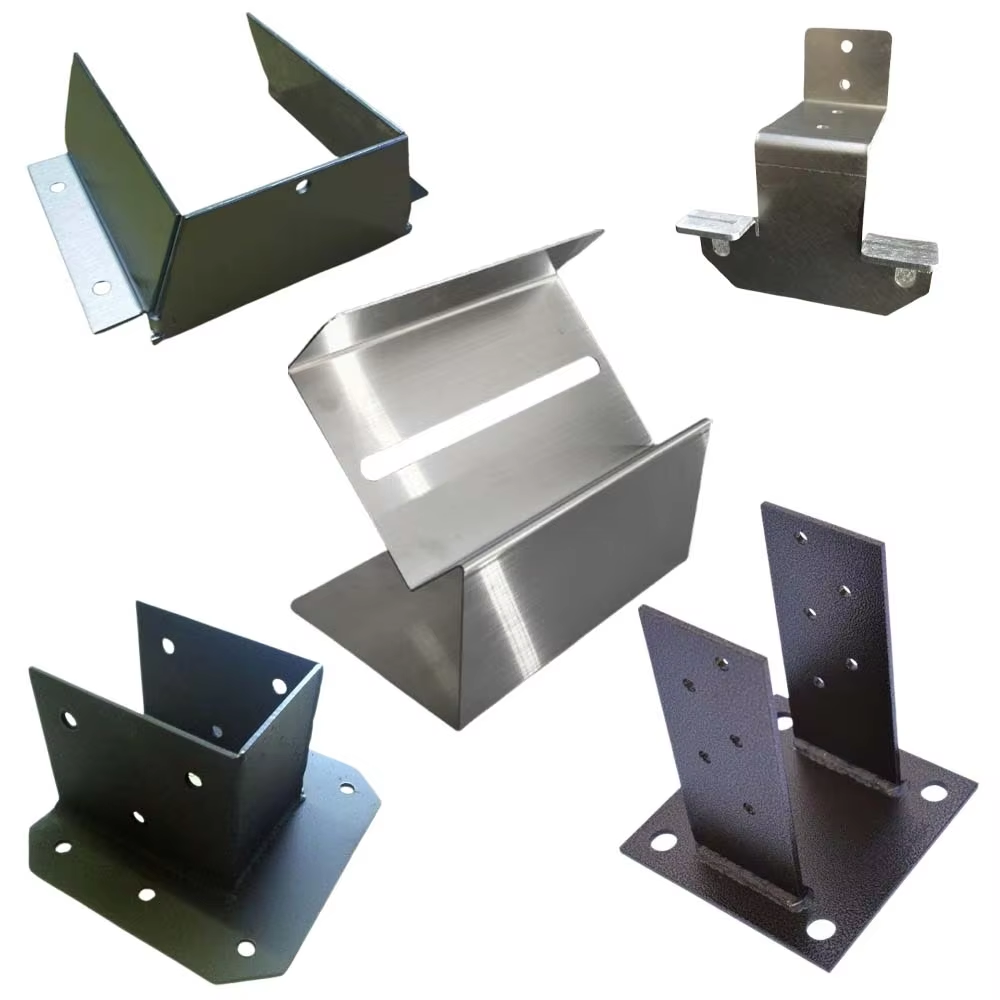

At Zhongshan Lambert Precision Hardware Co., Ltd., precision welding is at the core of our expertise. As an ISO-certified company established in 2012, we have specialized in high-end sheet metal and tubular fabrication for global industries for over 12 years. Our 6,000m² Industry 4.0 production base is equipped with advanced MIG/TIG welding machinery, ensuring that every precision welding project we undertake meets the highest standards of quality and accuracy. Whether it's for industrial enclosures, architectural metalwork, or public infrastructure components, our precision welding services guarantee structures that are not only structurally sound but also aesthetically pleasing. We understand the importance of precision in welding, and our skilled technicians work closely with clients to ensure every detail is perfect, from the initial design to the final product.